AHYW 400T4M CNC Press Brake 6 Axis DA66T Yawei made in china factory

Anhui Yawei Machine Tool is one professional sheet metal working machinery manufactures suppliers factory in China, our main products included CNC synchro press brakes(up to 12 axis), Conventional NC Brake press&metal bending machines, CNC Variable rake angle guillotine shears, NC metal shearing cutting machines, CNC Fiber Laser Cutting Machines 1kw,2kw,3kw,4kw,6kw&8kw

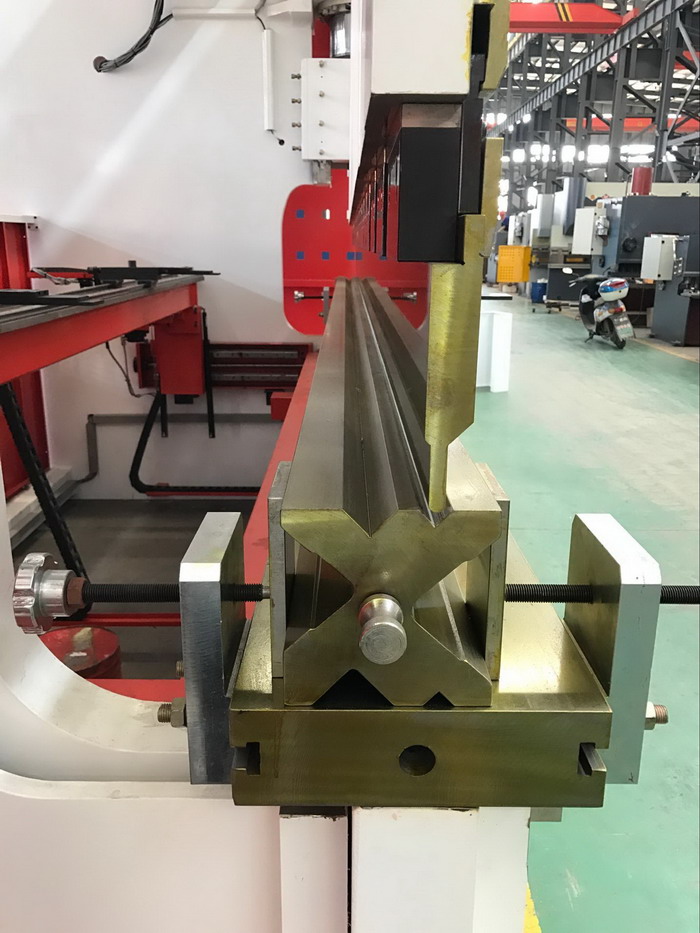

When you bending metal plate over 2.5m(8ft), it’s better to use crowning system controlled by CNC Press brake controller, due to machine frames material have deflection factors, the upper beam&lower beam will be deflected with concave shape, if no anti-deflection system, forsure the bending performance is not good, especially when operator is bending stainless steel for producing higher precision profiles, standard CNC hydraulic table have 3 units compensation cylinders mounted on lower beam, when operator enter the bending specifications in controller, the DA66T will calculated automatically and determine the crowning values, then give the compensation valves for oil pressure flow, the compensation cylinder will jack up the middle lower beam.

Italy DSP Laser guarding with MCS safety controller, UK and Italy CNC Press brake Market

Normally Making heavy plate bending more efficient is about more than effectively moving material to and from the press brake. Positioning, measuring, and adjusting the workpiece also affects the stability and repeatability of bending. Bending 4mm thin sheet with 3m or 4m will be cost less time and equipment, but if you are using 500T,600T,800T, eben 1000Tons press brakes for bending 4m to 6m metal sheet, lifting the material and feeding it to the bending area will be spent your more time and more tools, espcially when youa re running one over 1000Ton huge press brakes. Metal sheet bending material distortion is enemy No. 1 when it comes to bending parts quality. The less distortion, the better the quality of the bending. One way to minimize distortion is to support your material better.To keep the workpiece on an even course during bending, full cycle, try to use sheet supports. Placed in front of the press brake, these devices reinforce the sheet during bending cycle. The support arm makes full contact with the material, preventing material sagging ,especially bending thin and longer sheet, Heavy-duty followers can support large workpieces weighing up to several thousand pounds, depending on the make and model of the cnc controlled sheet follower system. Supports can include a sheet follower at the front and rear of the machine and a fixed or movable follower in the middle of the press brake.

The bending machine operator slides the supports into position and activates them via the machine controller. The sheet supports follow a synchronized process with top beam&bending tooling system, knowing exactly the angle they need to follow and the speed of the bending machine. They can support the total width of the workpiece using two internal motors: one axis moves vertically and another one rotates or swivels, which can ensure 100% synchro moving with top punch.

On extra-large press brakes, up to four support sheet supports are not uncommon. The number of support axes depends on the length of the machine and the length, width, and weight of the workpiece. 2000-3000ton big press brake uses three heavy-duty material support devices adjustable in the front and at the back along the length of the machine. Together, they serve as a table support for handling plate.

Sheet followers can work in combination with a press brake’s adaptive bending system. The most effective metal bending process uses the two accessories in concert to achieve repeatable accuracy.

Easy handling of the bending profiles is extremely important. The easier it is to move the metal sheet, the better assurance that you’ve gauged properly once metal pressing, which translates to better bend accuracy.

Huge sheet plate bending requires better material support at the front and back of the machine. In fact, it’s logical to have material support at the back of the press brake , as it’s easier and much less labor-intensive to push material against a stop than to pull it. This is also a matter of operator safety. It’s best to have the plate moving away from bending machine operator, pushing rather than pulling the sheet bending material. Increasingly, high-tonnage press brakes have pusher gauges in the front and back of the machine as well as extractors to push parts outside of the machine to a transport line,especially when bending over 12m longer metal electrical poles, cnc controlled feeding&pushing system will be big help for saving labor cost and increase poles bending precision and productvity.

If you want to know more technical specifications for AHYW Yawei 6 axis cnc press brake 400T4m DA66T or Italy ESA S640 6 axis cnc press brake with DSP MCS Laser safety guarding \. Please email us.

You may interested in Hybrid Pressbrakes, check the following links:

CNC Hybrid Press Brake machine is the latest high technology generation of Synchro press brake design, thanks to Germany Hoerbiger ePrAX Electro Hydraulic Hybrid system design.

Hybrid 6 axis CNC Press brake 3m125T, Italy ESA S640 Graphical controlelr, DSP Laser gaurding with MCS Laser safwety controller

Hot Tags: ahyw 400t4m cnc press brake 6 axis da66t, manufacturers China, suppliers China, made in China, factory, buy